Aerosol Containment & Extraction System

Conducting surgeries on patients suffering from "Air borne infectious" diseases poses a unique challenge to surgeons as these patients are capable of spreading their disease to others. This challenge is magnified multifold when aerosol generating procedures are carried out on these patients in an enclosed air conditioned space, such as an operating room. The current COVID scenario presents a very complicated challenge to the hospital management.

Product Description

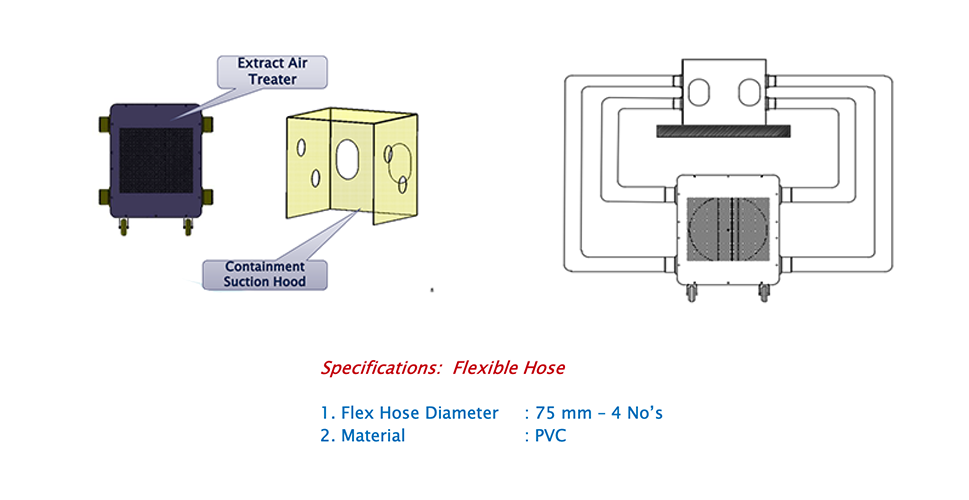

In some cases, emergency surgeries might be required for patients whose COVID status is unknown. In some cases, patients with a negative COVID test result on the day of surgery could turn out to be COVID positive a few days after the surgery. If the patient had turned out to be COVID positive on the day of the surgery, they could expose the surgical team to the risk of contracting the disease. Further more, it also could severely strain the financial and human resources in the hospital due to the mandatory screening and quarantine required for the exposed healthcare staff members. To mitigate this risk, many hospitals are converting their operating rooms from one working in a positive pressure to a negative pressure or into a non-re- circulatory air conditioning system. While this might prevent the spread of infectious agents expelled by the patient to the other parts of the hospital, it does not address the possibility of spread into the operating room environment, thereby putting the surgical team to a risk. In some cases, it could compromise the air quality inside the operating room leading to infections for the patient. Under these circumstances, PNUETRON ACES becomes the perfect companion to handle these risks and to protect the health care staff and the other patients in the hospital. PNEUTRON ACES can be used to effectively and quickly upgrade a standard operating room to a one that can be safely used for operating on patients with suspected or confirmed Airborne infectious diseases. PNEUTRON ACES would be very helpful to protect the surgical team, the operating room environment and the other people in the hospital from infection spread. The PNEUTRON ACES consists of a "Containment Suction Hood" (CSH) and a "Extract Air Treater" (EAT), interconnected with flexible ducts. The CSH is a passive enclosure, made of transparent poly carbonate material that acts as a containment hood. The CSH is positioned on the operating table covering the patient's head and neck. The EAT is a dynamic unit that extracts the air from the CSH, irradiates it through a UVGI zone (optional) and filters it through a HEPA filter before discharging it back into the operating room.

Operational Features:

- No specialised installation necessary. Just "Plug and play".

- Fast and easy to assemble and dismantle.

- Easy to move and transport.

- No modifications required to the existing infrastructure.

- Adequate access ports in the CSH to carryout medical procedures.

- Transparent walls to facilitate visual monitoring of the patient.

- Easily cleanable and dis-infectable.

- Movable flap to increase aerosol barrier in-flow. 9. Low power consumption.

- Low noise.

- Continuous operation.

Utility features:

- Physical isolation of the patient - Reduces infection spread.

- Negative pressure in the CSH - Aids containment of aerosols.

- Barrier air flow in to the CSH - Creates a virtual barrier between the patient and the surroundings.

- High air exchanges in the CSH - Facilitates dilution of infectious agents in the CSH.

- UVGI zone in EAT (Optional) - Irradiates the air to inactivate the bio aerosols.

- HEPA Filtration in the EAT - Filters and removes the infectious agents from the exhaust air.

- Air cleaning in the patient room - Provides additional air changes to the operating room.

Construction features:

- Transparent poly carbonate material for the CSH.

- Two access ports in the CSH (Additional ports can be provided on request).

- EAT casing made of powder coated steel.

- Tested & certified HEPA Filter in the EAT.

- Variable speed Centrifugal blower in the EAT.

- 4 no's of UVC lights in the EAT (optional).

- 4 no's of PVC flexible hoses connecting the CSH and EAT.

Meets requirements of:

- NSF 49